Mutsetse wekugadzira Margarine weBheki

Mutsetse wekugadzira Margarine weBheki

Mutsetse wekugadzira Margarine weBheki

Vhidhiyo Yekugadzira:https://www.youtube.com/watch?v=3cSJknMaYd8

Bhekari mutsetse wekugadzira margarineInosanganisira matanho akati wandei ekushandura zvinhu zvakagadzirwa kuita chigadzirwa chemafuta chinoparadzirwa, chinosanganiswa nemafuta. Pazasi pane pfupiso yezvinhu zvakakosha uye maitiro ari mumutsara wekugadzirwa kwemajarini:

1. Kugadzirira Zvinhu Zvisina Kugadzirwa

Kusanganisa Mafuta neMafuta– Mafuta emuriwo (emuchindwe, soya, sunflower, mhodzi dzerapeseed) anonatswa, anocheneswa, uye anobviswa munhuwi (RBD). Mafuta akaoma (senge palm stearin) anogona kuwedzerwa kuti awedzere kunaka.

- Kusanganisa Chikamu Chemvura– Mvura, munyu, zvinosanganisa makemikari (lecithin, mono/diglycerides), zvinochengetedza (potassium sorbate), uye zvinonaka zvinogadzirwa.

2. Kubatanidza

Mafuta nemvura zvinosanganiswa muchikamu chimwe nechimwetangi re emulsificationine zvinokurumidzisa zvakanyanya kugadzira pre-emulsion yakasimba (mvura-mu-mafuta).

Chiyero chakajairika: 80% mafuta, 20% chikamu chemvura (chinogona kusiyana kune mafuta mashoma).

3. Kuisa Pasteurization (Kurapa Nekupisa)

- Emulsion yacho inodziya kuti~70–80°Cmuplate heat exchanger yekuuraya utachiona uye kuona kuti zvinhu zvakafanana.

4. Kutonhodza & Kugadzira Makristalo (Sisitimu Yekuvhota)

Margarine inopfuura nepakati pechinoshandiswa pakupisa pamusoro pemvura chakakweshwa (SSHE)kanamuvhoti, uko inotonhodzwa nekukurumidza kuti iite kuti mafuta aite makristaro:

- Chikamu (Sirinda Yekutonhodza): Kutonhodza zvakanyanya4–10°Cinoumba makristaro madiki ane mafuta.

- B Unit (Mushandi wePin): Kushanda musanganiswa uyu kunoita kuti ganda rive rakatsetseka uye rirambe rakapfava.

- Chubhu Yekuzorora (C Unit): Inobvumira kugadzikana kwekristaro.

5. Kurongedza

- Michina yekuzadza margarineganhurira margarine mumabhavhu, muzviputiro (zvemargarine inonamirwa), kana mumidziyo mikuru.

- Kunyora Mazita & Kunyora Makodhi: Ruzivo rwechigadzirwa nenhamba dzebatch zvakadhindwa.

6. Kuongorora Kudzora Hunhu

- Magadzirirwo & Kupararira(penetrometry).

- Nzvimbo Yokunyunguduka(kuve nechokwadi chekuti tembiricha yemukamuri yagadzikana).

- Kuchengetedzwa kweMabhakitiriya(huwandu hweplate, mbiriso/mold).

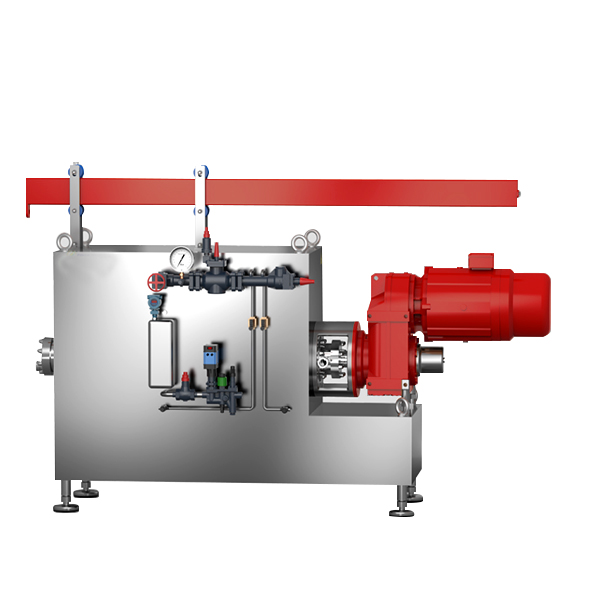

Midziyo inokosha muMargarine Line

| Midziyo | Basa |

| Tangi reEmulsification | Inosanganisa zvikamu zvemafuta/mvura |

| Chinochinja-chinja chePlate Heat | Inopasteurizes emulsion |

| Chinotsigisa Kupisa Pamusoro Chakakweshwa (Votator) | Kutonhora nekukurumidza & kupenya |

| Mushandi wePin (B Unit) | Inogadzirisa margarine |

| Machina ekuzadza Margarine & Packaging | Zvikamu muzvitoro |

Mhando dzeMargarine Dzinogadzirwa

- Puff Pastry Margarine: Yakagadzirwa nepurasitiki yakawanda, ine zvidimbu zvakasiyana-siyana

- Margarine yekeke: Inonaka uye ine simba rekufema zvakanaka

- Margarine inoputirwa: Nzvimbo yakanyanya kunyunguduka yekunyungudutsa

- Margarine yeBakery yezvinangwa zvose: Yakaringana kushandiswa kwakasiyana-siyana

Mhando Dzakasiyana-siyana

- Margarine Isina Trans: Inoshandisa mafuta akasanganiswa ne esterized pachinzvimbo chehydrogenation zvishoma.

- Margarine Inobva Muzvirimwa: Mafomu asina mukaka (emisika yevanodya nyama).

Kugadzira Nzvimbo