Mutsetse wekugadzira Muto weCustard

Mutsetse wekugadzira Muto weCustard

Mutsetse wekugadzira Muto weCustard

Vhidhiyo Yekugadzira:https://www.youtube.com/watch?v=AkAcycJx0pI

Amutsara wekugadzira muto wekasitadhiinosanganisira maitiro akasiyana-siyana ekugadzira custard sauce zvinobudirira, zvinoenderana, uye zvine hutsanana. Pazasi pane kupatsanurwa kwakadzama kwematanho akajairika ekugadzira custard sauce:

1. Kubata & Kugadzirira Zvinodiwa

- Kugamuchira Mukaka Uye Kuchengeta

- Mukaka usina kubikwa unogamuchirwa, woongororwa kuti wakanaka here, wozochengetwa mumasilos akachengetwa mufiriji.

- Imwe nzira: Upfu hwemukaka hwakagadziriswazve + mvura (kuti hugare kwenguva refu).

- Kubata Shuga neZvinotapira

- Shuga, sirapu yechibage, kana zvimwe zvinotapira zvinoyerwa uye zvinonyungudutswa.

- Kugadziriswa kweUpfu hweZai neZai

- Mazai emvura (akaiswa pasteurized) kana kuti upfu hwemazai anosanganiswa nemvura.

- Starch & Stabilizers

- Chibage chegorosi, starch yakagadziriswa, kana zvinosimbisa (semuenzaniso, carrageenan) zvinosanganiswa kare kudzivirira kuungana kwevhu.

- Zvinonhuwira & Zvinowedzerwa

- Vanilla, caramel, kana zvimwe zvinonaka, pamwe chete nezvinhu zvinochengetedza (kana zvichidikanwa), zvinogadzirwa.

2. Kusanganisa & Kusanganisa

- Kusanganisa kweBatch kana Kuenderera Mberi

- Zvimisikidzo zvinosanganiswa mumusanganiswa wekupisa zvakanyanyakanatangi risati rasanganiswapasi pekupisa kwakadzorwa (kudzivirira kukora nguva isati yakwana).

- Kubatanidzwa kwehomogenization kunogona kushandiswa kuti pave nekunaka kwakapfava.

3. Kubika & Kuisa Pasteurization

- Kubika Nguva Dzose (Scrapped Surface Heat Exchanger)

- Musanganiswa wacho unodziiswa kuti75–85°C (167–185°F)kuti ushandise starch gelatinization uye kuti muto wacho unyatsosimba.

- Kuisa pasteurization (HTST kana Batch)

- Nguva Pfupi Yekupisa Kwakakwirira (HTST) pa72°C (161°F) kwemasekonzi 15-20kana kuti pasteurization yebatch kuti pave nechokwadi chekuti utachiona hwakachengeteka.

- Danho rekutonhodza

- Kutonhora nekukurumidza kusvika4–10°C (39–50°F)kurega kuramba uchibika uye kuchengetedza magadzirirwo.

4. Kubatanidzwa kweHomogenization (Sarudzo)

- Homogenizer Yekudzvanywa Kwakanyanya

- Inoshandiswa pakuita kuti ganda rive rakatsetseka zvakanyanya (inodzivirira kusviba kwetsanga).

5. Kuzadza & Kurongedza

- Michina yekuzadza otomatiki

- Kuzadza homwe(zvekutengesa) kanakuzadza zvakawanda(yebasa rezvekudya).

- Kuzadza kweAseptic(kwekugara kwenguva refu) kanakuzadza nekupisa(yekuchengetera zvinhu munzvimbo inotonhorera).

- Mafomati ekurongedza:

- Mabhodhoro epurasitiki, makatoni, mabhegi, kana magaba.

- Kushambidza nitrogen kunogona kushandiswa kuwedzera nguva yekugara kwayo.

6. Kutonhodza & Kuchengeta

- Kupisa kwemhepo (kana zvichidikanwa)

- Kana muine custard mufiriji, inotonhorera nekukurumidza kusvika4°C (39°F).

- Kuchengetera Zvinhu Zvinotonhora

- Yakachengetwa pa4°C (39°F)ye custard itsva kana kuti yezvigadzirwa zvakarapwa neUHT.

7. Kudzora Hunhu & Kuedzwa

- Kuongorora Kusviba(vachishandisa maviscometer).

- Kutarisa pH(chinangwa: ~6.0–6.5).

- Kuedzwa kweMicrobiological(huwandu hweplate, mbiriso/mold).

- Kuongorora Kunzwa(kuravira, magadzirirwo, ruvara).

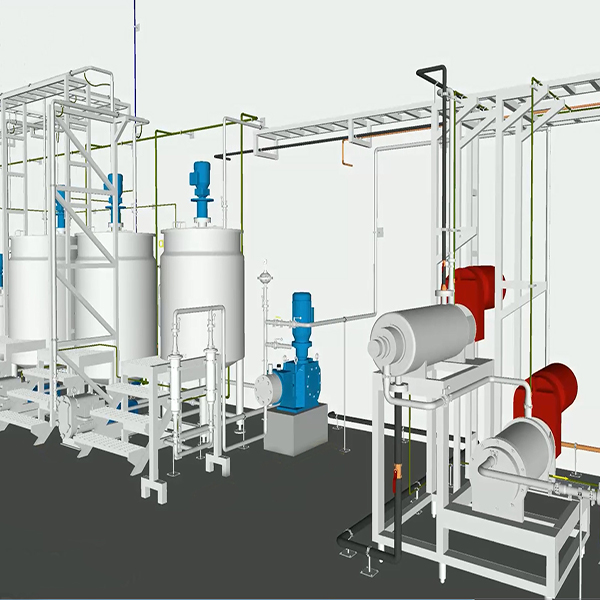

Midziyo mikuru muCustard Sauce Production Line

- Matangi Ekuchengetera Zvinhu(yemukaka, zvinhu zvemvura).

- Masisitimu ekuyera uye ekuyeresa.

- Matangi eHigh-Shear & Premix.

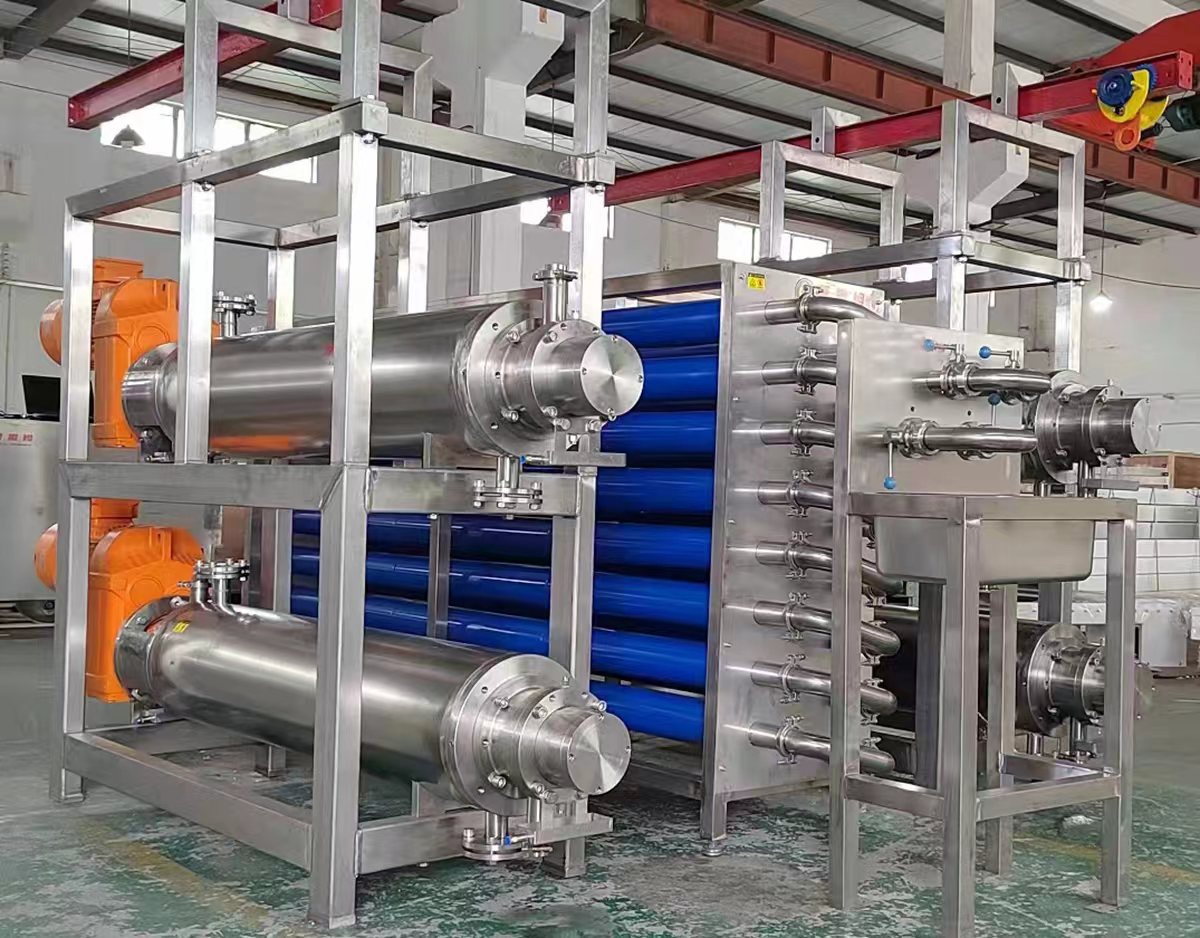

- Chinopa Pasteurizer (HTST kana Batch).

- Chinochinja-chinja kupisa pamusoro chakakweshwa (chekubikira).

- Homogenizer (sarudzo).

- Michina yekuzadza (piston, volumetric, kana aseptic).

- Matuneru Ekutonhodza.

- Michina yekurongedza (kuvhara, kunyora mazita).

Mhando dzeCustard Sauce dzinogadzirwa

- Custard Yakachengetwa muFriji(nguva pfupi yekushanda, kuravira kutsva).

- UHT Custard(inogara kwenguva refu, yakacheneswa).

- Musanganiswa weCustard yeUpfu(yekugadzirisazve).

Kuzvigadzira otomatiki & Kushanda Nesimba

- Masisitimu Ekudzora ePLCkuti ikwanise kudzorwa zvakanaka uye kusanganiswa kwemvura.

- Masisitimu eCIP (Clean-in-Please)zvehutsanana.

Kugadzira Nzvimbo

Nyora meseji yako pano woitumira kwatiri