Margarine Production Technology

PFUPISO YE EXECUTIVE

Makambani echikafu nhasi akafanana nemamwe mabhizinesi ekugadzira asingatarise chete kuvimbika uye mhando yemidziyo yekugadzira chikafu asiwo pamasevhisi akasiyana siyana anogona kupihwa nemupi wemidziyo yekugadzirisa. Kunze kwemitsara yekugadzira inoshanda yatinoendesa, isu tinogona kuve mubatsiri kubva kune yekutanga zano kana nhanho yeprojekiti kusvika pachikamu chekupedzisira chekutumira, tisingakanganwe yakakosha mushure memusika sevhisi.

Shiputec vane makore anopfuura makumi maviri 'ruzivo rwekugadzira chikafu uye kurongedza indasitiri.

NHUNGAMIDZO YEDU TECHNOLOGY

KUONA NEKUZVIPIRIRA

Shiputec segment inogadzira, inogadzira uye misika inogadziridza engineering uye otomatiki mhinduro kumukaka, chikafu, chinwiwa, chemugungwa, chemishonga uye chekuchengeta maindasitiri kuburikidza nekuita kwayo kwepasirese.

Isu takazvipira kubatsira vatengi vedu pasi rese kuvandudza mashandiro uye pundutso yechigadzirwa chavo chekugadzira uye maitiro. Isu tinozadzisa izvi nekupa huwandu hwakasiyana hwezvigadzirwa uye mhinduro kubva kune enjiniya magadzirirwo ezvidyarwa zvakazara zvinotsigirwa neinotungamira pasi rose kunyorera uye hunyanzvi hwekuvandudza.

Isu tinoenderera mberi nekubatsira vatengi vedu kukwirisa mashandiro uye pundutso yechirimwa chavo mukati mehupenyu hwayo hwesevhisi nemasevhisi erutsigiro akagadzirirwa kune zvavanoda ivo pachavo kuburikidza neyakarongwa sevhisi yevatengi uye spare parts network.

CUTOMER FOCUS

Shiputec inovandudza, inogadzira uye inoisa mitsara yemazuva ano, inoshanda uye yakavimbika yekugadzira indasitiri yechikafu. Kugadzira zvigadzirwa zvemafuta akacheneswa semajarini, bhotela, kupararira uye kupfupisa Shiputec inopa zvigadziriso izvo zvinosanganisirawo mitsetse yemaitiro emulsified chikafu zvigadzirwa senge mayonnaise, sosi uye madhirezi.

MARGARINE PRODUCTION

Margarine uye zvigadzirwa zvine hukama zvine chikamu chemvura uye chikamu chemafuta uye nekudaro chinogona kuratidzwa semvura-mu-mafuta (W / O) emulsions umo chikamu chemvura chinoparadzirwa zvakanaka semadonhwe muchikamu chemafuta chinoenderera. Zvichienderana nekushandiswa kwechigadzirwa, kuumbwa kwechikamu chemafuta uye nzira yekugadzira inosarudzwa maererano.

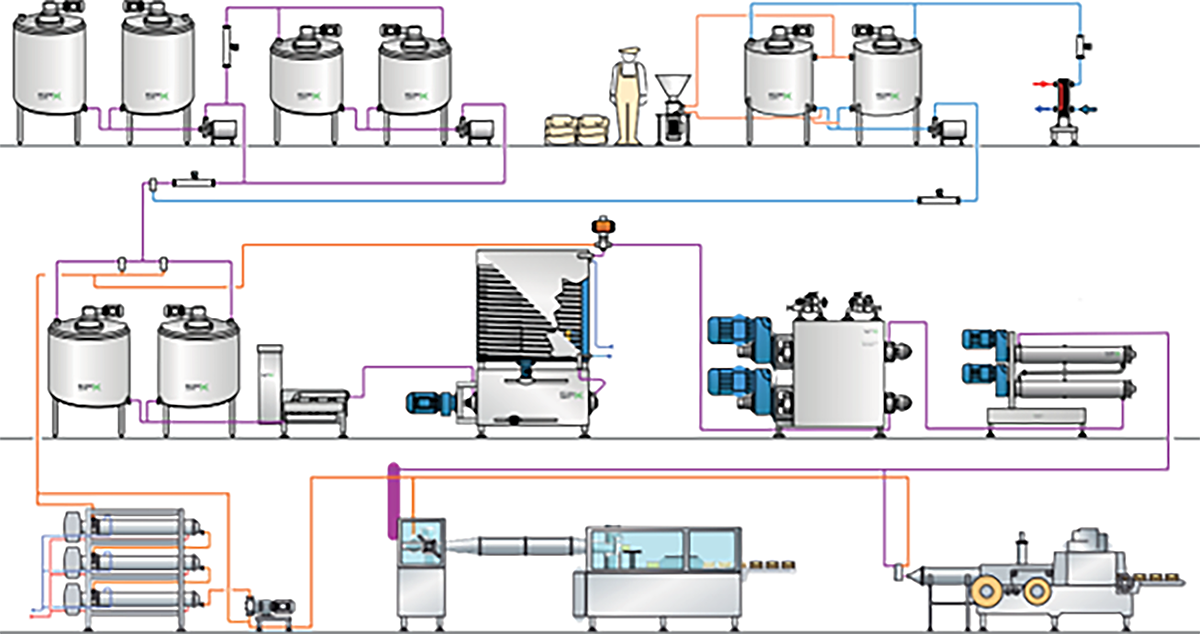

Kunze kwemidziyo yekristalllization, nzvimbo yemazuva ano yekugadzira majarini uye zvigadzirwa zvinoenderana nazvo zvinowanzo sanganisira matangi akasiyana-siyana ekuchengetedza oiri pamwe ne emulsifier, chikamu chemvura uye emulsion kugadzirira; saizi uye nhamba yematangi inoverengerwa zvichienderana nekugona kwechirimwa uye chigadzirwa portfolio. Iyo nzvimbo inosanganisirawo pasteurization unit uye remelting nzvimbo. Saka, maitiro ekugadzira anogona kazhinji kukamurwa kuita anotevera maitirwo (tapota ona diagiramu 1):

KUGADZIRIRWA KWECHIKAMU CHEMVURA NECHIKAMU MAFUTA (ZONE 1)

Chikamu chemvura chinowanzo gadzirirwa batch-wise mutangi remvura. Mvura inofanira kuva yemhando yakanaka yekunwa. Kana kunwa kwemhando yepamusoro kusingagone kuvimbiswa, mvura yacho inogona kugadziridzwa isati yagadzirwa nenzira semuenzaniso UV kana sefa system.

Kunze kwemvura, chikamu chemvura chinogona kuva nemunyu kana brine, mapuroteni emukaka (tafura margarine uye kupararira kwemafuta mashoma), shuga (puff pastry), stabilizers (yakaderedzwa uye yakaderera mafuta anopararira), kuchengetedza uye mvura inonyunguduka.

Izvo zvakakosha zvinongedzo muchikamu chemafuta, musanganiswa wemafuta, unowanzo sanganisira musanganiswa wemafuta akasiyana nemafuta. Kuti uwane majarini ane hunhu hunodiwa uye mashandiro, chiyero chemafuta nemafuta musanganiswa wemafuta chinogadzirisa kuita kwechigadzirwa chekupedzisira.

Mafuta akasiyana-siyana nemafuta, angave semusanganiswa wemafuta kana oiri imwe chete, anochengetwa mumatangi ekuchengetedza oiri anowanzo kuiswa kunze kwenzvimbo yekugadzira. Izvi zvinochengetwa pakatsiga tembiricha yekuchengetera pamusoro pekunyungudika kwemafuta uye pasi pekusuduruka kuitira kudzivirira kupatsanurwa kwemafuta uye kubvumira kubata nyore.

Kunze kwekusanganiswa kwemafuta, chikamu chemafuta chinowanzo kuve nemafuta madiki-anonyungudika zvinhu senge emulsifier, lecithin, flavour, ruvara uye antioxidants. Izvi zvidiki zvimisikidzwa zvinonyungudutswa mumusanganiswa wemafuta chikamu chemvura chisati chawedzerwa, nekudaro isati yaitwa emulsification.

EMULSION PREPARATION ( ZONE 2 )

Iyo emulsion inogadzirwa nekuendesa akasiyana mafuta uye mafuta kana mafuta anosanganiswa kune emulsion tank. Kazhinji, mafuta akanyunguduka kana mafuta akasanganiswa anowedzerwa kutanga achiteverwa nemafuta epasi anonyunguduka uye mafuta emvura. Kuti apedze kugadzirira kwechikamu chemafuta, emulsifier uye mamwe madiki anonyungudika emafuta anowedzerwa kumafuta akasanganiswa. Kana zvese zvinoshandiswa zvechikamu chemafuta zvakasanganiswa zvakanaka, chikamu chemvura chinowedzerwa uye emulsion inogadzirwa pasi pekusanganiswa kwakanyanya asi kunodzora.

Masisitimu akasiyana anogona kushandiswa metering akasiyana emulsion ayo maviri ari kushanda batch-wise:

Kuyerera kwemamita system

Weighing tank system

A inoenderera in-line emulsification sisitimu inosarudzika zvishoma asi yakashandiswa mhinduro mune semuenzaniso mitsetse yepamusoro apo nzvimbo shoma yematangi emulsion inowanikwa. Iyi sisitimu iri kushandisa dosing pombi uye misa inoyerera metres kudzora reshiyo yezvikamu zvakawedzerwa mudiki emulsion tank.

Masisitimu ataurwa pamusoro anogona kudzorwa zvizere otomatiki. Zvimwe zvidyarwa zvekare, zvisineyi, zvichine masisitimu ekugadzirira emulsion nemaoko asi aya anoda basa uye haakurudzirwe kuisa nhasi nekuda kwemitemo yakasimba yekutevera.

Iyo yekuyerera mita sisitimu yakavakirwa pabatch-huchenjeri emulsion gadziriro umo zvikamu zvakasiyana-siyana uye zvimisikidzo zvinoyerwa nemamita ekuyerera kwemamita pazvinotamiswa kubva kune akasiyana nhanho gadziriro matangi kupinda mu emulsion tank. Kurongeka kwegadziriro iyi ndiko +/-0.3%. Iyi sisitimu inoratidzirwa nekusanzwa kwayo kune zvekunze zvinofurira senge vibrations uye tsvina.

Iyo yekuyera tangi system yakafanana neyekuyerera mita sisitimu yakavakirwa pabatch-huchenjeri emulsion kugadzirira. Pano huwandu hwezvigadzirwa uye zvikamu zvinowedzerwa zvakananga kune emulsion tank iyo yakasungirirwa pamasero anotakura anodzora huwandu hwakawedzerwa kune tangi.

Kazhinji, maviri-tangi sisitimu inoshandiswa pakugadzirira emulsion kuitira kuti ikwanise kumhanyisa mutsara wekristalllization uchienderera. Tangi yega yega inoshanda segadziriro uye buffer tank (emulsion tank), saka mutsara wekristalllization uchapihwa kubva kune rimwe tangi nepo batch nyowani ichagadzirirwa mune imwe uye zvinopesana. Iyi inonzi flip-flop system.

Mhinduro iyo iyo emulsion inogadzirirwa mune rimwe tangi uye kana yakagadzirira inotamirwa kune buffer tangi kubva kune iyo crystallization mutsara inopihwa zvakare sarudzo. Iyi sisitimu inodaidzwa kuti premix/buffer system.

PASTEURIZATION ( ZONE 3 )

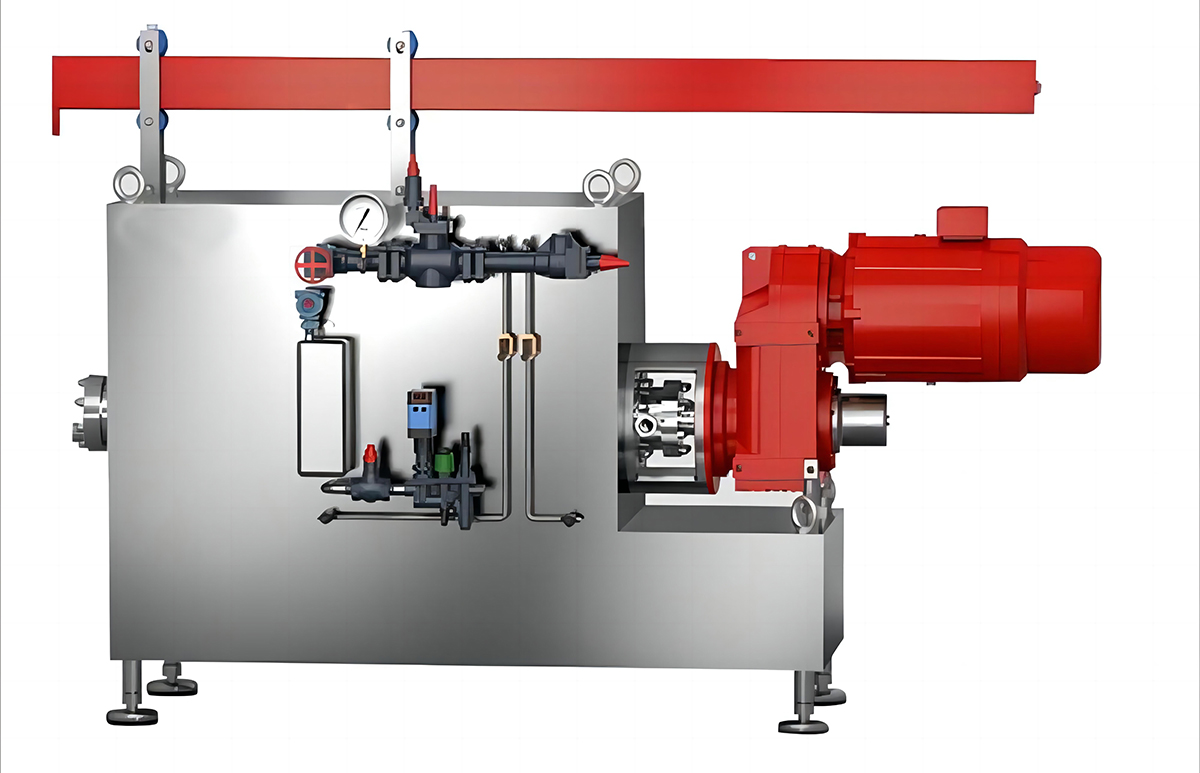

Kubva mubhafa tangi iyo emulsion inogara ichipomba kuburikidza nendiro yekupisa exchanger (PHE) kana yakaderera pressure scraped surface heat exchanger (SSHE), kana high pressure SSHE ye pasteurization isati yapinda mumutsara wecrystallization.

Kune akazara mafuta zvigadzirwa PHE inowanzo shandiswa. Kune yakaderera mafuta shanduro apo emulsion inotarisirwa kuratidza yakanyanyisa viscosity uye yekupisa-inonzwisisa emulsions (eg emulsions ine yakakwira protein yemukati) iyo SPX system seyakaderera kudzvinyirira mhinduro kana iyo SPX-PLUS seyakanyanya kudzvanywa mhinduro inokurudzirwa.

Iyo pasteurization maitiro ane akawanda mabhenefiti. Inochengetedza kudziviswa kwekukura kwebhakitiriya uye kukura kwezvimwe zvipenyu zviduku, nokudaro kuvandudza microbiological kugadzikana kwemulsion. Pasteurization yechikamu chemvura chete inogoneka, asi pasteurization ye emulsion yakazara inofarirwa sezvo pasteurization maitiro emulsion anozoderedza nguva yekugara kubva pasteurized chigadzirwa kusvika pakuzadza kana kurongedza yekupedzisira chigadzirwa. Zvakare, chigadzirwa chinorapwa mu-in-line process kubva pasteurization kusvika pakuzadza kana kurongedza kwechigadzirwa chekupedzisira uye pasteurization yechero rework zvinhu inovimbiswa kana emulsion yakazara pasteurized.

Mukuwedzera, pasteurization ye emulsion yakakwana inovimbisa kuti emulsion inodyiswa kune crystallization mutsara pane imwe nguva tembiricha ichiwana nguva dzose kugadzirisa parameters, chigadzirwa tembiricha uye chigadzirwa kugadzirwa. Mukuwedzera, kuitika kwe-pre-crystallized emulsion yakadyiswa kune crystallization midziyo inodzivirirwa apo emulsion yakanyatsogadziriswa uye inodyiswa kune yakakwirira yekumanikidza pombi pakupisa 5-10 ° C yakakwirira kudarika nzvimbo yekunyunguduka kwechikamu chemafuta.

Iyo yakajairika pasteurization process ichaita mushure mekugadzirira emulsion pa45-55 ° C inosanganisira kudziyisa uye kubata kutevedzana kweemulsion pa75-85 ° C kwe16 sec. uyezve kutonhora kunosvika ku45-55°C. Kupisa kwekupedzisira kunoenderana nekunyunguduka kwechikamu chemafuta: iyo yakakwirira yekunyungudika, iyo yakanyanya tembiricha.

KUCHIRA, KUKATAMIRA NOKUKUKA (ZONE 4)

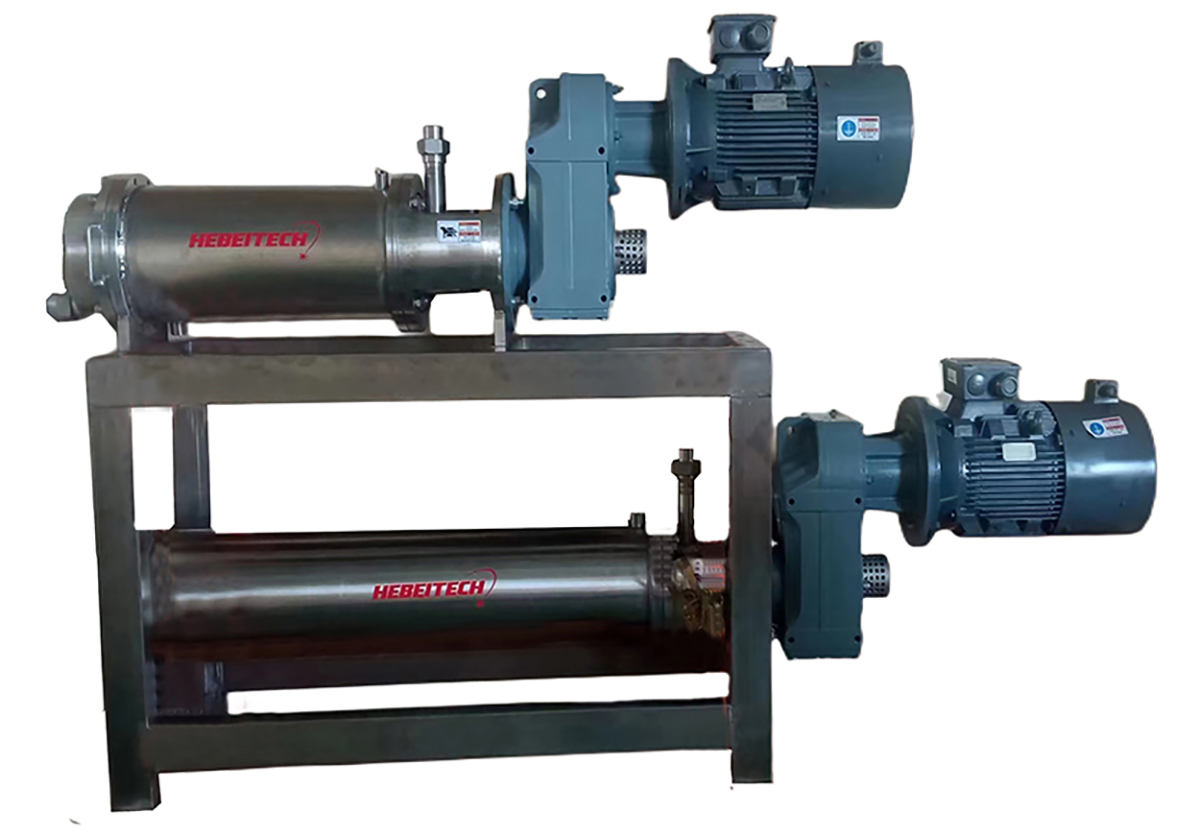

Iyo emulsion inoputirwa kumutsara wekristalllization nenzira yekumanikidza kwepiston pombi (HPP). Mutsetse wecrystallization wekugadzirwa kwemajarini uye zvigadzirwa zvine hukama zvinowanzo sanganisira yakanyanya kudzvanywa SSHE iyo inotonhodzwa neammonia kana Freon mhando yekutonhodza midhiya. Pin rotor muchina (s) uye/kana epakati makristasi anowanzo kuverengerwa mumutsara kuitira kuwedzera kuwedzera kukanya kusimba uye nguva yekugadzira zvigadzirwa zvepurasitiki. Imwe yekuzorora chubhu ndiyo nhanho yekupedzisira yekristaro mutsara uye inongosanganisirwa kana chigadzirwa chakazara.

Mwoyo we crystallization mutsara ndiyo yakanyanya kudzvanywa SSHE, iyo inodziya emulsion inotonhorera-yakatonhorera uye yakakwenenzverwa mukati memukati weinotonhora chubhu. Iyo emulsion inokwenenzverwa kubva kune inotenderera scrapers, saka iyo emulsion inotonhorera uye yakakanya panguva imwe chete. Kana mafuta ari mu emulsion achipenya, makristasi emafuta anoumba matatu-dimensional network achipinza madonhwe emvura uye mafuta emvura, zvichikonzera zvigadzirwa zvine zvimiro zvepurasitiki semi-yakasimba hunhu.

Zvichienderana nerudzi rwechigadzirwa chinofanirwa kugadzirwa uye rudzi rwemafuta anoshandiswa kune chimwe chigadzirwa, kumisikidzwa kweiyo crystallization mutsara (kureva kurongeka kwemachubhu ekupisa uye epini rotor michina) inogona kugadziridzwa kuti ipe iyo yakanyanya kurongeka yechigadzirwa.

Sezvo mutsara wekristalllization unowanzo gadzira zvinopfuura chimwe chigadzirwa chemafuta, iyo SSHE inowanzova nezvikamu zviviri kana kupfuura zvinotonhorera kana kutonhora machubhu kuitira kuti isangane nezvinodiwa zve flexible crystallization line. Paunenge uchigadzira zvakasiyana-siyana zvigadzirwa zvemafuta zvakasanganiswa zvakasiyana-siyana, kuchinjika kunodiwa sezvo maitiro ekristalllization emusanganiswa anogona kusiyana kubva kune mumwe musanganiswa kuenda kune mumwe.

Iyo crystallization process, mamiriro ekugadzirisa uye maparamendi ekugadzirisa ane pesvedzero huru pane hunhu hwekupedzisira margarine uye kuparadzira zvigadzirwa. Paunenge uchigadzira mutsara wekristalllization, zvakakosha kuziva maitiro ezvigadzirwa zvakarongwa kugadzirwa pamutsara. Kuti uchengetedze mari yeramangwana, kuchinjika kwemutsara pamwe chete neanogona kudzora maparamita ega ega anodiwa, sezvo huwandu hwezvigadzirwa zvekufarira hunogona kuchinja nekufamba kwenguva pamwe chete nemidziyo.

Kugona kwemutsara kunotarirwa nenzvimbo inotonhorera inowanikwa yeSSHE. Michina yehukuru hwakasiyana inowanikwa kubva kune yakaderera kusvika kune yakakwirira mitsetse. Zvakare madhigirii akasiyana ekuchinjika anowanikwa kubva kune imwechete chubhu michina kune akawanda chubhu mitsara, nekudaro inochinjika mitsetse yekugadzirisa.

Mushure mokunge chigadzirwa chacho chanyungudutswa muSSHE, inopinda mumushini wepini rotor uye / kana crystallizers yepakati iyo inokandwa kune imwe nguva yenguva uye nehumwe simba kuitira kuti ibatsire kusimudzirwa kwematatu-dimensional network, iyo pane macroscopic level ndiyo chimiro chepurasitiki. Kana chigadzirwa chacho chichida kugoverwa sechigadzirwa chakaputirwa, chichapinda muSSHE zvakare chisati chagadzikana muhubhu yekuzorora isati yaputirwa. Kana chigadzirwa chikazadzwa mumakapu, hapana chubhu yekuzorora inosanganisirwa mumutsara wecrystallization.

KUPAKA, KUZADZA UYE KUKANGARIRA ( ZONE 5 )

Yakasiyana-siyana yekurongedza uye yekuzadza michina iripo pamusika uye haitsanangurwe muchinyorwa ichi. Nekudaro, kuwirirana kwechigadzirwa kwakasiyana zvakanyanya kana ichigadzirwa kuti itakurwe kana kuzadzwa. Zviripachena kuti chigadzirwa chakazara chinofanirwa kuratidza chimiro chakasimba kupfuura chigadzirwa chakazadzwa uye kana chimiro ichi chisina kunyatsonaka chigadzirwa chinozoendeswa kune inonyungudutswa system, yakanyungudutswa uye yowedzerwa kubhafa tangi kuti igadziriswe zvakare. Masisitimu akasiyana ekudzoreredza aripo asi anonyanya kushandiswa masisitimu ndeye PHE kana kuderera kudzvinyirira SSHE.

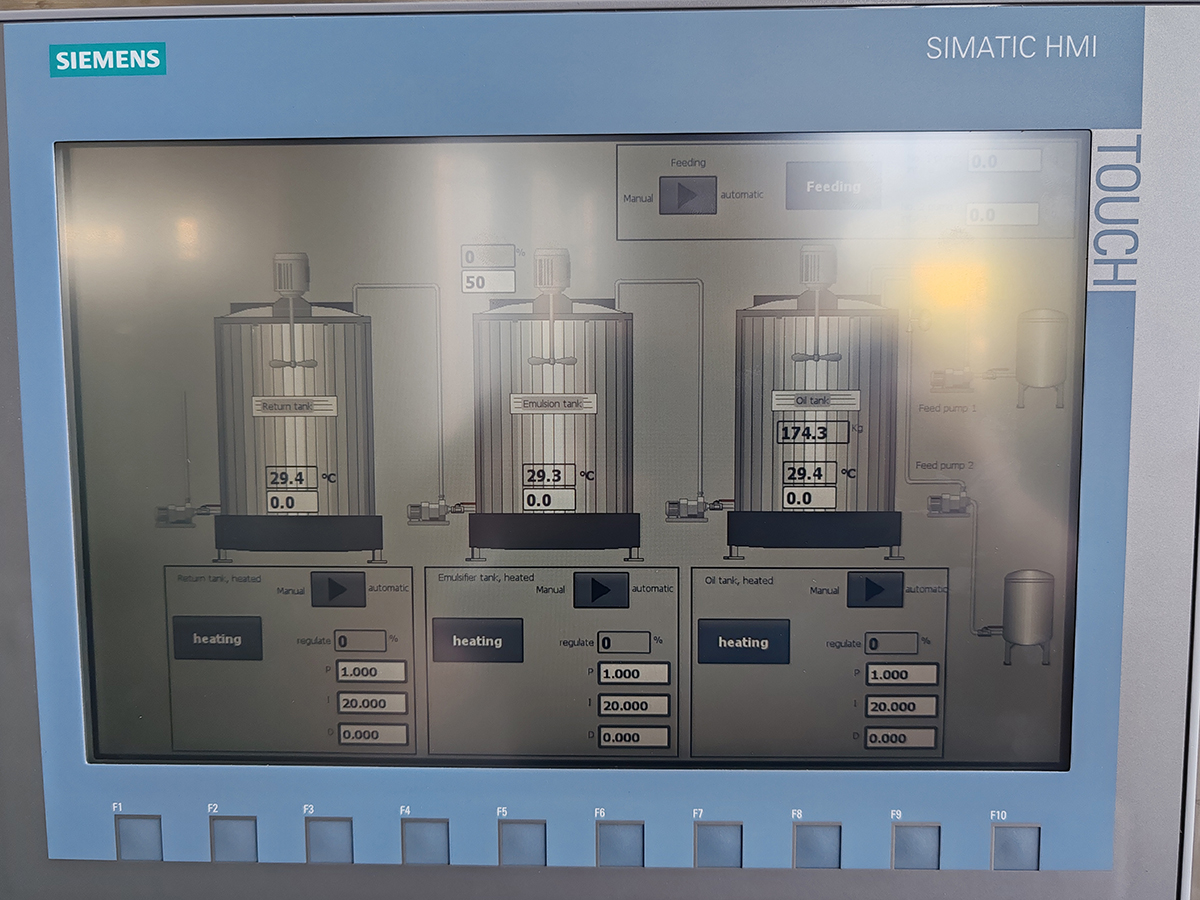

AUTOMATION

Margarine, sezvimwe zvigadzirwa zvechikafu, iri mumafekitori mazhinji nhasi anogadzirwa pasi pemaitiro akasimba ekutevera. Aya maitiro anowanzo kuvharira zvinongedzo, kugadzirwa uye chigadzirwa chekupedzisira hachigumiri mukuchengetedzeka kwechikafu chete asiwo muhutano hwechikafu hunogara huripo. Traceability zvido zvinogona kuitwa mukudzora sisitimu yefekitori uye Shiputec control system yakagadzirirwa kudzora, kurekodha uye kunyora akakosha mamiriro uye ma paramita ane chekuita nekugadzira kwakazara maitiro.

Iyo yekudzora sisitimu inoshongedzerwa nepassword kuchengetedza uye inoratidzira nhoroondo yekutema data yeese maparamendi anosanganisirwa mutsetse wekugadzirisa margarine kubva kuruzivo rwerecipe kusvika kuongororo yekupedzisira yechigadzirwa. Kudhindwa kwe data kunosanganisira kukwanisa uye kubuda kwepombi yepamusoro (l / awa uye kumashure kwekumanikidzwa), kutonhora kwechigadzirwa (incl. pasteurization process) panguva yekristalllization, kutonhora kwekushisa (kana kutonhora kwema media media) kweSSHE, kukurumidza kweSSHE nemichina yepini rotor pamwe chete nemutoro wemotor inoshandisa pombi yepamusoro, iyo SSHE nemichina yepini rotor.

Kudzora system

Panguva yekugadzirisa, maalarm anotumirwa kune anoshanda kana maparameter ekugadzirisa echigadzirwa chakananga kunze kwemiganhu; idzi dzakaiswa mupepeti yekubikira isati yagadzirwa. Aya maaramu anofanirwa kubvumwa nemaoko uye zviito zvinoenderana nematanho anofanirwa kutorwa. Maalarm ese anochengetwa munhoroondo yealarm system kuti ionekwe gare gare. Kana chigadzirwa chichisiya mutsara wekugadzira mune yakanyatso kurongedzerwa kana yakazadzwa fomu, iri kunze kwezita rechigadzirwa rinowanzo kunyorwa nezuva, nguva uye batch nhamba yekuzivikanwa yekutevera kunotevera. Iyo yakazara nhoroondo yematanho ese ekugadzira anosanganisirwa mukugadzira maitiro anoiswa nekuda kwekuchengetedzwa kwemugadziri uye mushandisi wekupedzisira, mutengi.

CIP

CIP yekuchenesa zvidyarwa (CIP = kucheneswa panzvimbo) zvakare chikamu chemazuva ano majarini sezvo zvirimwa zvinogadzira majarini zvichifanira kucheneswa nguva nenguva. Zvechinyakare zvigadzirwa zvemajarini kamwe pasvondo inguva yekuchenesa nguva. Nekudaro, kune zvigadzirwa zvinonzwisisika semafuta akaderera (yakakwirira mvura yemukati) uye/kana yakakwira mapuroteni ane zvigadzirwa, nguva pfupi pakati peCIP inokurudzirwa.

Muchidimbu, maitiro maviri eCIP anoshandiswa: CIP zvidyarwa zvinoshandisa kuchenesa midhiya kamwe chete kana yakakurudzirwa CIP zvirimwa zvinoshanda kuburikidza nebuffer mhinduro yekuchenesa midhiya uko midhiya yakaita seye, asidhi uye / kana disinfectants inodzoserwa kune yega CIP matangi ekuchengetera mushure mekushandiswa. Iyo yekupedzisira maitiro inofarirwa sezvo ichimiririra mhinduro yezvakatipoteredza uye iri mhinduro yehupfumi maererano nekushandiswa kwekuchenesa maajenti uye nekudaro mutengo weizvi.

Kana mitsara yakati wandei yekugadzira yakaiswa mufekitori imwe, zvinokwanisika kumisikidza parallel yekuchenesa tracks kana CIP satellite masisitimu. Izvi zvinoguma nekuderera kukuru kwekuchenesa nguva uye kushandiswa kwesimba. Iwo maparamendi eiyo CIP maitiro anodzorwa otomatiki uye anonyorerwa kuti azoteedzere gare gare mune yekutonga system.

KUPEDZISIRA MASHOKO

Paunenge uchigadzira majarini uye zvigadzirwa zvinoenderana nazvo, zvakakosha kuyeuka kuti hazvisi izvo chete zvinongedzo semafuta nemafuta anoshandiswa kana resipi yechigadzirwa iyo inotaridza kunaka kwechigadzirwa chekupedzisira asiwo magadzirirwo echirimwa, maparamita ekugadzirisa uye mamiriro echirimwa. Kana mutsara kana midziyo isina kuchengetedzwa zvakanaka, kune ngozi yokuti mutsara hausi kunyatsoita. Naizvozvo, kugadzira zvigadzirwa zvemhando yepamusoro, chirimwa chinoshanda zvakanaka chinofanirwa asi kusarudzwa kwemafuta musanganiswa ane hunhu hunoenderana nekupedzisira kushandiswa kwechigadzirwa kwakakosha zvakare pamwe nekumisikidza kwakaringana uye sarudzo yekugadzira maparamita echirimwa. Chekupedzisira asi chisiri chidiki chigadzirwa chekupedzisira chinofanira kubatwa tembiricha zvichienderana nekushandiswa kwekupedzisira.

Nguva yekutumira: Zvita-19-2023