Mutsetse weKugadzira Margarine wePuff Pastry

Mutsetse weKugadzira Margarine wePuff Pastry

Vhidhiyo Yekugadzira:https://www.youtube.com/watch?v=3cSJknMaYd8

Margarine inotsiva bota inogadzirwa nemafuta emuriwo, mafuta emhuka kana mamwe mafuta. Maitiro ayo ekugadzira uye michina yekugadzirisa yakura zvakanyanya mushure memakore ekugadzirwa. Zvinotevera maitiro akadzama uye kuiswa kwemidziyo mikuru:

I. Maitiro Ekugadzira Margarin

1. Kugadzirira Zvinhu Zvisina Kugadzirwa

• Zvinhu zvikuru zvekushandisa:

o Mafuta (anenge 80%): akadai semafuta emuchindwe, mafuta esoya, mafuta erapeseed, mafuta ekokonati, nezvimwewo, ayo anoda kunatswa (kubvisa gumming, kubvisa acidization, kubvisa ruvara, kubvisa kunhuhwirira).

o Chikamu chemvura (inenge 15-20%): mukaka wakabviswa mafuta, mvura, munyu, zvinosanganisa mafuta (zvakaita se lecithin, mono-glyceride), zvinochengetedza (zvakaita se potassium sorbate), mavhitamini (zvakaita se vitamin A, D), zvinonhuhwirira, nezvimwewo.

o Zvinowedzerwa: ruvara (β-carotene), acidity regulator (lactic acid), nezvimwewo.

2. Kusanganisa uye Kubatanidza

• Kusanganisa chikamu chemafuta nechikamu chemvura:

o Chikamu chemafuta (mafuta + zvinowedzerwa zvinonyungudika mumafuta) chinopiswa kusvika 50-60℃ uye chinonyungudika.

o Chikamu chemvura (mvura + zvinowedzerwa zvinonyungudika mumvura) chinodziiswa uye chinonatswa (pasteurization, 72℃ / 15 seconds).

o Mapato maviri aya anosanganiswa zvakaenzana, uye ma emulsifiers (akadai se mono-glyceride, soy lecithin) anowedzerwa, uye emulsion yakafanana (yemvura-mu-mafuta kana yemafuta-mu-mvura) inogadzirwa kuburikidza nekukurunga nekukurumidza (2000-3000 rpm).

3. Kutonhodza nekukurumidza uye kujekesa (Nhanho Yakakosha)

• Kutonhodza nekukurumidza: Emulsion inotonhodzwa nekukurumidza kusvika pa10-20℃ kuburikidza ne scraped surface heat exchanger (SSHE), zvichiita kuti mafuta acho aite crystallization zvishoma kuti agadzire β' crystal form (kiyi yekugadzirwa kwakanaka).

• Kuumba: Mafuta akaomarara anochekwa nemaoko kuburikidza nemudziyo wekukanyira (Pin Worker) pa2000-3000 rpm kuti apwanye makristaro makuru uye agadzire chimiro chemafuta chakafanana, zvichidzivirira kunzwa kwegrit.

4. Kukura uye Kurongedza

• Kukura: Inosiyiwa kuti imire pa20-25℃ kwemaawa 24-48 kuti igadzire chimiro chekristaro.

• Kurongedza: Inozadzwa semabhuroko, makapu, kana rudzi rwespray, uye inochengetwa mufiriji (mamwe majarini akapfava anogona kuchengetwa patembiricha yemukamuri zvakananga).

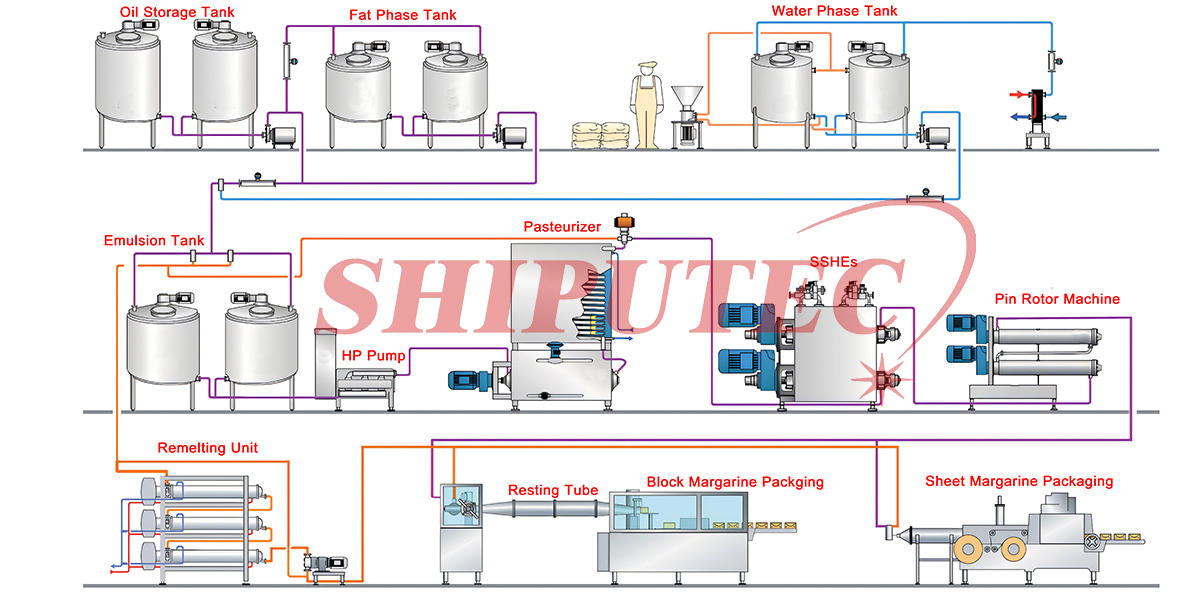

II. Midziyo Yekugadzirisa Yepakati

1. Midziyo yekurapa isati yatanga

• Midziyo yekuchenesa mafuta: kubvisa gumming centrifuge, shongwe yekubvisa acid, tangi yekubvisa ruvara, shongwe yekubvisa kunhuhwirira.

• Midziyo yekugadzirisa mvura: muchina wekuisa pasteurization, homogenizer ine pressure yakakwira (inoshandiswa pakuisa mukaka kana mvura muchikamu chimwe chete).

2. Midziyo yeEmulsification

• Tangi reEmulsion: tangi resimbi isina ngura rine mabasa ekukurunga nekudziya (senge paddle kana turbine type stirrer).

• Homogenizer ine kumanikidzwa kwakanyanya: wedzera kunatsa madonhwe emulsion (kumanikidzwa 10-20 MPa).

3. Midziyo Inotonhodza Nekukurumidza

• Chinotsigisa Kupisa Pamusoro Pemvura (SSHE):

o Inotonhodza nekukurumidza kusvika yaoma, nechinhu chinotenderera kuti isakwenya.

o Makambani akajairika: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (USA), Shiputec (China)

• Mushandi wePin:

o Cheka mafuta kuburikidza nemapini akawanda kuti udzore saizi yekristaro.

4. Midziyo yekurongedza

• Muchina wekuzadza otomatiki: wezvidhinha (25g-500g) kana kurongedza mabhareni (1kg-20kg).

• Mutsetse wekurongedza usina utachiona: wakakodzera zvigadzirwa zvinogara kwenguva refu (zvakadai semargarine yemvura yakacheneswa neUHT).

III. Mhando dzeMaitiro

1. Margarine Yakapfava: Mafuta akawanda emvura ari mumafuta (akadai semafuta ezuva), hapana chikonzero chekutonhodza nekukurumidza, anogadzirwa zvakananga uye akaiswa mupurasitiki.

2. Margarine isina mafuta akawanda: Mafuta ari pakati pe40-60%, anoda kuwedzerwa zvinhu zvinoita kuti mafuta acho akodze (senge gelatin, starch yakagadziriswa).

3. Margarine inogadzirwa nemiti: Fomura yemafuta ezvirimwa zvese, isina mafuta anogadzirwa nemafuta (gadzirisa nzvimbo yekunyunguduka kuburikidza nekuchinjana kwemaester kana tekinoroji yekupatsanura).

IV. Pfungwa Huru dzeKudzora Hunhu •

Chimiro chekristaro: Chimiro chekristaro cheβ' (chinopfuura chimiro chekristaro cheβ) chinoda kudzora mwero wekudzima uye simba rekusanganisa.

• Kuchengetedzwa kwehutachiona: Chikamu chemvura chinofanira kucheneswa zvakasimba, uye pH inofanira kugadziriswa pasi pe4.5 kudzivirira mabhakitiriya.

• Kugadzikana kweokisijeni: Wedzera ma antioxidants (akadai seTBHQ, vhitamini E) kudzivirira kusvibiswa kwema ion esimbi.

Kuburikidza nekusanganiswa kwemaitiro nemidziyo iri pamusoro apa, kirimu yemazuva ano yekugadzira inogona kutevedzera kuravira kwebhota uku ichisangana nezvinodiwa zvehutano zvakaita secholesterol shoma uye mafuta mashoma akazara. Fomura chaiyo uye maitiro acho zvinofanirwa kugadziriswa zvichienderana nenzvimbo yechigadzirwa (senge pakubika kana kushandisa panzvimbo dzechikafu).

Kugadzira Nzvimbo